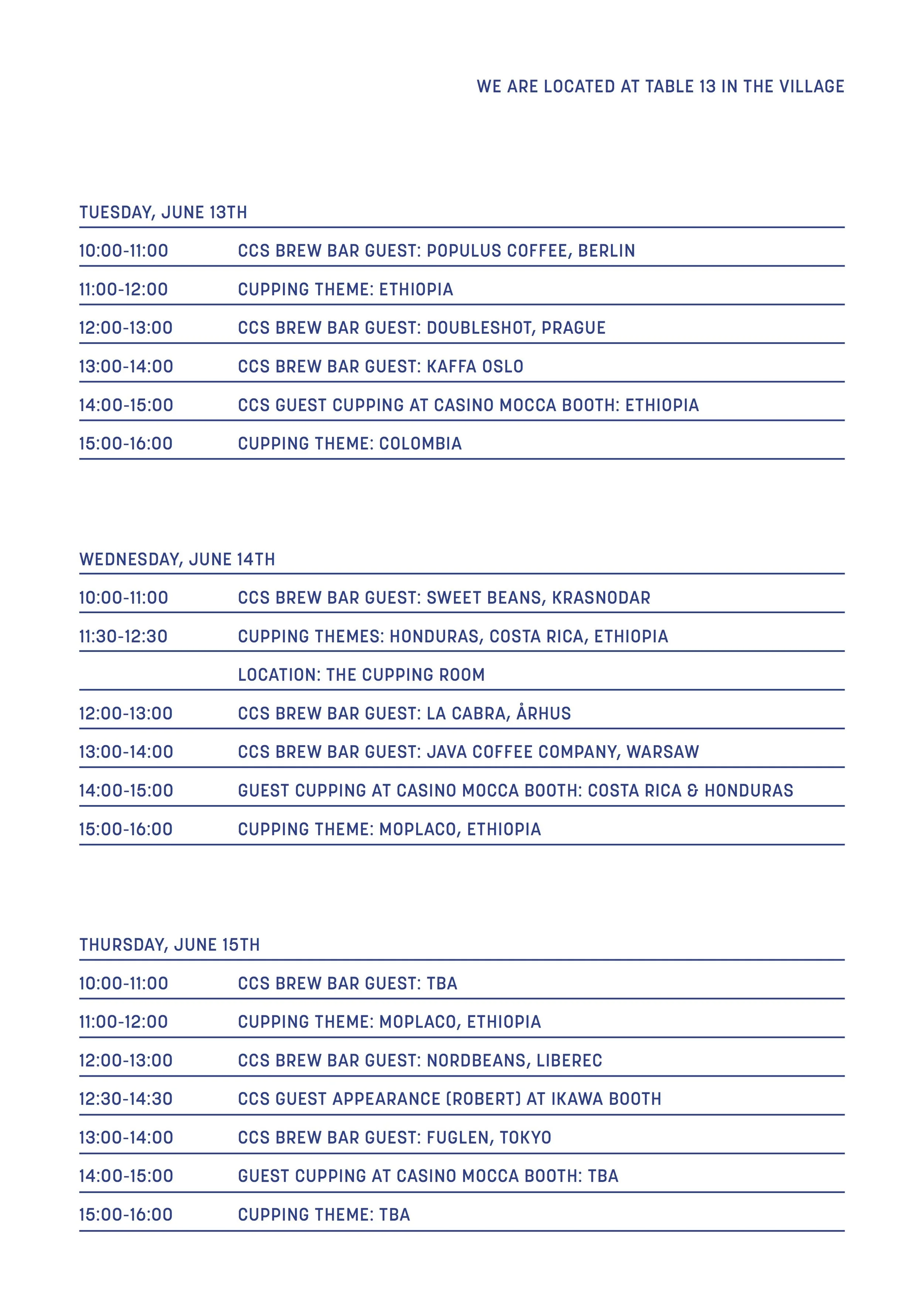

Cuppings, Brew Bar featuring your favourite roasters across Europe & more

CCS IS HIRING!

The Collaborative Coffee Source (CCS) is looking for self-motivated individuals to join our team

If you have any of the following, get in touch!

- Industry Experience (must)

- Cupping skills

- A Lab & Quality control background

- Are Service & Sales oriented

- Are self-driven, organized, a people-person

- Have outstanding communication skills

We are a quality and education focused green coffee sourcing company founded in Oslo, Norway and are concurrently expanding from our New York headquarters to cover more of the North American market, as well as from Shanghai to better serve our rapidly growing Asian markets.

CCS currently sources coffee in nine countries from Central America, South America and East Africa. We serve roasters from all over North America, Europe and Asia.

Send your cover letter and CV to robert@collaborativecoffeesource.com.

Panama Harvest Visit, March 2017

The purpose of my recent visit to Boquete, Panama was to spend a couple of days cupping with long-time friends and partners. Over the course of this visit, I observed and learned about the latest developments concerning how coffee cultivation has changed in this famed micro-region. My hosts and the coffees we cupped included:

- Hacienda Esmeralda, Geishas, Washed and Naturals

- Elida Estate, Catuaí and Geisha, Washed and Naturals

- Panama Coffee Traders (PCT): the new sourcing and export company of Wilford and Wilford Lamastus Jr. of Finca Elida. Catuaí and Geisha, Washed and Naturals.

This visit proved to be a bit early ‘in the season’ for cupping, although mid-March isn’t typically early in Central America. One major reason for this comparatively “later” harvest period is that the farmers we are buying from, along with many more in the Boquete valley, are growing their best coffees at higher and higher altitudes, in part due to climate change.

Climate Change, Geisha & the Harvest Period

Ronaldo, who has been working with coffee farming in Boquete over three decades (most notably at La Hacienda Esmeralda) is unequivocal about the average temperature noticeably increasing upward over the years. Rain patterns have also been changing; there is later or irregular rain, leading to “irregular” flowering and harvest periods. The harvest period is now starting in December lasting in August, with the main harvest period going from February through April.

The farmers in Boquete are incredibly competitive and they have long been rivalling one another in growing Geisha trees at the climactically highest altitudes possible. Early on this meant exceeding 1900 meters above sea level, then 2000 and today, ‘high’ has increased to 2100 masl. What was once not even considered possible is now happening, due both to competition and climate change. What’s next?

Ripe geisha cherries at La Hacienda Esmeralda

Regardless of temperature or climate change, the Geisha plant is a sturdy one once it has settled. But it is also delicate and slow growing in terms of producing fruit worth calling a harvest. These factors, along with the high altitudes, the fact that Geisha cultivation requires seven to eight years or more of careful husbandry, the necessary wind protection, nourishment, and waiting, all culminate in the Geishaendeavour requiring great investments in time and all other imaginable resources.

The coffees themselves are becoming more elegant, whether wet processed or other. I think that when it is well done, Geisha might be one of the best varieties to make naturals from. I’m not saying that natural processing makes for a better cup than washed per se. But the best version of this variety and this method is showing its best and true attributes here. These Geisha naturals showcase the processing method in such a way that makes for both complexity and balance: they have all the floral notes and structured acidity, together with all the sweetness, body, and juiciness that a 94-points kind-of-coffee ought to have.

Hacienda Esmeralda

During the weekend of my visit, La Hacienda Esmeralda was celebrating its 50th Anniversary. The farm started with dairy production during the late ‘60s, moved into coffee soon afterward and is today strong in both fields. In the coffee world, Esmeralda is The World's #1 most recognized farm for Geisha coffee. After all, it was the Peterson family that discovered it. Who even spoke about Geisha before the Best of Panama competition in 2004?

Happy 50th Anniversary, La Hacienda Esmeralda! Big congrats to the Peterson Family.

Earlier, I mentioned Ronaldo who has been working with the Peterson family since 2002. He arrived when they bought the now-famous plot on the Jaramillo hillside where the first Geisha trees were discovered. Back then, Geisha trees were being harvested from an altitude range of 1450 to 1650 masl. Much has changed since then.

Esmeralda continues to dry their lots on cement patios and in mechanical driers. There has been little innovation there. Their meticulousness, however, is unquestionable, along with their coffees’ cup results. As a matter of fact, I have yet to see the same consistency in results from other markets. I’m thinking particularly about colleagues from across the border in Costa Rica, who claim theirs are the best practices when it comes to drying naturals and ‘honey’ coffee on raised African beds. I’m wondering whether these methods truly make a difference.

What are the cup-profile correlations? And what are the long-term effects of a given method? How well does the processed green coffee keep its quality?

Robert (left) with Wilford Lamastus of Finca Elida

Finca Elida and Designing Flavour

Speaking of processing and cup quality, Wilford Lamastus of Finca Elida told me he is growing more and more skeptical of de-pulping machines (i.e. eco-pulpers). He thinks it is obvious that the pulper’s physical strain on the parchment, including the centrifuging of the mucilage, is damaging the coffee-in-parchment to an extent that is limiting the quality potential of the coffee both in the cup and over time.

While I understood his evidence as anecdotal, I think it is worth following up. Wilford now processes his best coffee without de-pulping. Rather, the skin is removed using good old-fashioned fermentation and washing techniques, which he calls hand washed coffee. I like that.

This classic process uses more water, so for this is a problematic trend (if it becomes one, again) in terms of environmental considerations. On the other hand, and this became clear to me later in the conversation with Wilford, the other motivation for taking the cherry-skin off carefully is to preserve the skin as well as possible so he can make the best possible cascara from it. Some good news for the same environmental analyses.

Drying at Finca Elida

Elida’s lots, both washed and natural, are generally cupping great, with scores ranging from 86 to 89 points (the family might have scored them higher). There were only a few scoring a disappointing 84 points and then the family knew something had gone wrong, whether in the drying or in the roasting. There were also cups that were (un)questionably winey, but then again, these are spot-on for other buyers’ preferences. So it goes.

Like those winey flavors in your naturals and want more? You’ve got it! The Elida approach to servicing a market, by designing flavor, is something we are seeing in other places in the coffee world too. Wilford is adamant about this approach being a pragmatic one. From his perspective as a craftsman, the ‘secret’ lies in the drying of naturals. For those that want a cleaner cup with less mature-fruit driven flavors, he will suggest a faster dried coffee cherry: one dried on a hotter surface; using thinner layers; with more sun exposure and more raking; over 5-7 days. Done! For a fruitier cup for other markets, he will deliberately do a slower drying by using raised African beds, thicker layers, less shade or less direct sunlight, turning just once a day, with a two-week drying time, or more.

Pricing

Beyond the yearly ritual of cupping with Rachel (at Esmeralda) and Wilford & Wilford Jr. (at Elida), I learned a few things about how Boquete producers strategize their production and sales, even designing profiles of their lots to meet various markets. It has been evident for years that Boquete is the home of Geisha in quite literal, as well as statistical senses. There is a tremendous amount of Geisha plants being grown, whether it’s the re-planting of existing farm land, or new plantings. The Lamastus' farms alone will plant 45,000+ trees this year, which is on par with their growth last year. Given the time it takes to see any noticeable harvest, production levels aren’t going to explode any time soon.

The Petersons, easily already the biggest Geisha farmers in this community, continue to buy land and grow trees at a formidable rate. They do so in no rush and with no cutting of corners. The family work with coffee based on solid investments and farm work. I often think that we owe a great deal of gratitude to the fact that it was this family, and this community, that discovered Geisha. Had it been somebody else, what would they have done? Would the field have advanced to where it is today?

The Petersons: (from left) Daniel, Rachel, Erik, Susan & Price)

Auctions continue to be a thermometer and a regulator for the price setting of Geisha coffee, although, going from astronomically high prices of $300+ per pound, to more down-to-earth levels of $30/lb and below speaks clearly, in dollar value terms, that not all Geisha lots are ‘worth' the same. At BoP and at Esmeralda’s very own auctions, the lots are very competitive in quality. For example, Esmeralda is not auctioning any lot under 88-points. This means that when they sell their Private Collection, it is a blend of 86-88 points, which is not a bad deal, considering that one does not need to bid for it.

Farmers delivering to and succeeding at Best of Panama know that they cannot expect to sell their non-auction 86-point Geishas at +$30 per pound. While I think these price-structures are interesting and well deserved, we must realize that there is a new economy in coffee that is separate from and totally different than the rest of the coffee market. Like in any other well-functioning economy, knowledge is power. In Boquete, cupping is key, and the best farmers in this town are also the best cuppers, competing with their customers in knowing the most about what’s on the table. When these coffees meet an educated market, offered by empowered farmers, it is a quite beautiful battle. One that is ‘fought’ on equal terms.

The Best of Panama Auction has been instrumental in empowering Panama coffee farmers in setting great benchmark prices for their lots

Elida sells its Catuaí cascara for $3.50/lb and its Geisha for $10/lb. Power!

This year, the Lamastuses introduced me to their Panama Coffee Traders' (PCT) program for sourcing and buying lots from neighbours. This company was started with the aim of finding buyers good and sold Boquete coffees that are at a lower price-point. While my visit proved to be a bit early in the season, I still cupped some lots and have asked about places, people and potential for future relationships. I scored one non-Geisha from PCT at 86 points and the highest scores were between 86.5 and 87-points but both were Geisha.

Well, the season isn’t over and symptomatically of climate change and coffee growing at higher altitudes, the BoP which used to take place in Early-April is now happening at the end of May. Hopefully you, the buyer, will accept these realities and not fill up your inventories with other Central American coffees, while Boquete coffee have not yet been harvested.

- Robert

SCA x CCS 2017

We will be cupping a curated selection of our coffees: available, soon to be available, along with some stunners that simply need revisiting.

Date: Sunday, April 23, 2017

Time: 10:15 a.m. – 12:00 p.m.

Location: The Cupping Exchange, Room 618

Honduras

From the currently harvesting. Showcasing long-time friends and new acquaintances from Santa Barbara, which produces some of our most interesting Central American offerings coming from some of our longest-standing relationships.

Moreno Family, El Cedral, Santa Barbara

Guatemala

A selection of some of the most versatile coffees we offer. Featuring cups from Antigua & Huehuetenango.

Luis Pedro Zelaya Zamora, Bella Vista Mill

Kenya

Charles Cardoso from Kenyacof will be on hand to discuss the flight of freshly harvested coffees (on offer), along with the ups and downs of the just completed harvest season.

Mary Maina, Manyeki Estate

Ethiopia

From mainstays to our first international presentation of newly established relationships with cooperatives in the Agaro region.

Asnake Nigat of Kata Muduga Union

Colombia

Alejandro Renjifo of Fairfield Trading will accompany the presentation of our Acevedo lots, freshly arrived and meticulously curated during the Acevedo Cup Competition from December 2016.

Alejandro Renjifo (R) with Acevedo Cup winner Fernando Bustos (C) & Eduardo Urquina of Fairfield Trading (L)

Burundi

Ben Carlson from Long Miles Coffee joins us as we cup and reflect on how stunning these Burundian coffees have been and what it took to get them there.

Ben Carlson (L) with Jeremie Nakimuhana (C) from Long Miles with a farmer from Mikuba Hill

Sal, Martell, Robert and David will be on hand to talk about the coffees, the origins, and also CCS, our model and fielding inquiries/interest on working together.

Our session is open to the public. The room is set for 30 people, with 25/30 spots already confirmed.

Get in touch with Sal to secure these last spots. He will also be happy to schedule a meeting with you should you not be able to attend the cupping.

Farmer Profile: Dario Hernandez

Farm & Production Data

Farm Name: Dario Hernandez

Owner: Dario, Angelica & Tono Hernandez. A family of three (Tono is Dario’s and Angelica’s son) – each with their own plantation making up the farm as a whole

Closest town: Antigua

Department: Sacatepéquez

Altitude (masl): 1600-1800

Farm Size (ha): 17.5

Approximate number of trees planted per hectare: 3400

Soil composition: volcanic

Harvest season: January – April

Harvest peak: Mid-February – Mid-March

Approx. annual production (per 46kg bags green coffee): 300

Varieties: Bourbon & caturra

Wet process

Washing - Cherries go into reception tank and floaters are separated out, then pumped into the depulper - After being depulped by a mechanical depulper, cherries are sorted in two ways: clean and those that still have fruit o The ones with fruit go to a separate channel to undergo a second depulping - Clean cherries are moved with recycled water over to fermentation tanks o If there happen to still be cherries with fruit, they are sent to another tank where they will most likely be processed as commercial grade - Dry fermentation for 14-15 hours - Clean water then used to rinse the parchment which is then moved to a mechanical washer and finally transported to the drying patios or beds.

Three types of drying methods. Dependent on quality:

- Green house with raised beds • Used for small lots (e.g. Hunapu). Do some honeys and naturals • Temperature, moisture, humidity levels are monitored • There are windows that can be opened to allow for more air flow when needed

- Mechanical dryers used for biggest/commercial lots • Stay in the dryer for 24 hours @ below 50C • Then dried for five days on the patio

- Patio

- Most volume dried here

- 12-16 days

- Tube test in the middle of coffee lots to figure out whether coffee is dry enough to be measured for 11% moisture content. If it sticks to the tube, it still needs drying. If it doesn’t, moisture content reading is taken.

- Post-drying - Parchment is packed in grain pro and rests for 30 days - At the dry mill, there are three different mechanical sorters that grade by A (biggest), B and C (smallest) o This process is repeated at least seven times to ensure even grading - Finally, the coffee is deparched and packaged.

Other Data

Other crops grown: avocado, used for family consumption

Number of people employed at farm: 8-10 family members work on the farm; an additional 12-14 pickers hired during the peak of harvest. Most of these are friends of the family. A law was recently passed in Guatemala that requires employers to register workers as employees and this provides them with government social and healthcare benefits that they didn’t previously have access to.

Pickers’ wage: 50-70 GTQ/45kg.

About the farmer & plans for the farm

The Hernandez family comes from a long lineage of coffee farmers and it’s easy to see this, walking through Dario’s plantation, which is neatly planted, pruned and seeing the health of the coffee plants. Although disease (roya and ojo de gayo) remain the family’s biggest challenges to coffee production, the family has, together with the Zelcafé team, managed to find the right inputs, use of labour (e.g. selective pruning) and tools to quickly manage outbreaks of disease before they become unmanageable. A result of their careful management is that the family can safely say that inputs are largely organic in composition. The family’s main goal for the future is to expand the size of plantations. Land is very expensive, however, so for now, good and regular management of the farm is the focus. About Bella Vista & Zelcafé

Background

Luis Pedro Zelaya Zamora (LPZZ) is the fourth generation in his family to be working in the coffee business. The Zelaya family’s first farm was Carmona, followed by Bella Vista, which where the wet, dry mill facilities, and Zelcafé staff offices were later built and are currently located.

For many years, the family’s business focus was on commercial coffee production and export but in 2000, LPZZ began developing and changing Zelcafé’s focus into specialty coffee/microlots, with the support of some early clients. Over time Zelcafé has been able to successfully transition the business into solely focusing on specialty coffee. For the Zelaya family, their coffee endeavours are not only about business; their aim is to provide a good basis for generations of their family and community to come. With this in mind, they are constantly looking for ways to provide jobs to as many families in their communities as possible, as well as supplying the best quality coffee they can to their clients.

Partnerships & Services

The family has worked with small producers in Antigua since they first started coffee farming. New relationships almost always come from introductions from families already working with the Zelaya family, ensuring close and stable partnerships. In addition to buying cherries from farms, Bella Vista also manages estate farms that owners don't want to sell but don't know how manage themselves.

The Bella Vista team take care of all the planning, execution and monitoring of the resources each farm they own or manage have: human, technical, financial, and knowledge/training. In the case of the small producers that they buy cherries from, the team not only buy cherries at a premium, they also provide technical assistance and the financing of inputs. Bella Vista is constantly looking to improve its agricultural activities to reduce chemicals to a minimum and in turn share their scientific knowledge with other farms.

Bella Vista continuously encourages its workers to get proper education and in special cases, finances education for some of them. The facility also often offers workshops on different topics. The Zelaya family farms all have C.A.F.E Practices implemented and in the coming years the family will try to implement a WaSH project at one of their biggest farms.

Other future plans include research on water treatment and the building of treatment plants and hopefully, the construction of another greenhouse.

Farm Profile: La Soledad

Lucía Zelaya with her husband, Ronny Asensio

Farm & Production Data

Farm Name: La Soledad

Owner: Lucía Zelaya

Farm manager(s): Julio Pablo Damian & Ronny Asensio

Closest town: Antigua

Department: Sacatepéquez

Altitude (masl): 1600-1800

Farm Size (ha): 12.5; 10 planted with coffee

Approximate number of trees planted per hectare: 3500

Soil composition: Clay mixed with volcanic and sandy loam

Harvest season: Late-December – Early-April

Harvest peak: Mid-February – Mid-March

Approx. annual production (per 46kg bags green coffee): 400

Varieties: 30% bourbon; 70% caturra

Manager: Julio Pablo Damian

Wet process

Washing - Cherries go into reception tank and floaters are separated out, then pumped into the depulper - After being depulped by a mechanical depulper, cherries are sorted in two ways: clean and those that still have fruit o The ones with fruit go to a separate channel to undergo a second depulping - Clean cherries are moved with recycled water over to fermentation tanks o If there happen to still be cherries with fruit, they are sent to another tank where they will most likely be processed as commercial grade - Dry fermentation for 14-15 hours - Clean water then used to rinse the parchment which is then moved to a mechanical washer and finally transported to the drying patios or beds.

Three types of drying methods. Dependent on quality:

- Green house with raised beds •

- Used for small lots (e.g. Hunapu). Do some honeys and naturals

- Temperature, moisture, humidity levels are monitored

- There are windows that can be opened to allow for more air flow when needed

- Mechanical dryers used for biggest/commercial lots

- Stay in the dryer for 24 hours @ below 50C

- Then dried for five days on the patio

- Patio •

- Most volume dried here

- 12-16 days

- Tube test in the middle of coffee lots to figure out whether coffee is dry enough to be measured for 11% moisture content. If it sticks to the tube, it still needs drying. If it doesn’t, moisture content reading is taken.

Post-drying - Parchment is packed in grain pro and rests for 30 days - At the dry mill, there are three different mechanical sorters that grade by A (biggest), B and C (smallest) o This process is repeated at least seven times to ensure even grading - Finally, the coffee is deparched and packaged.

Other Data

Number of people employed at farm: 5 permanent; 15-20 pickers. A law was recently passed in Guatemala that requires employers to register workers as employees and this provides them with government social and healthcare benefits that they didn’t previously have access to.

Pickers’ wage: 50-70 GTQ/45kg.

About the farmer & the farm’s management

Lucía Zelaya comes from both a well-established and long-standing coffee producing family. She is both a cousin of Luis Pedro Zelaya and is herself a 4th generation producer. Her husband, Ronny, also comes from coffee producing heritage and owns another separate coffee farm, manages yet another, on top of overseeing the management of La Soledad.

It is in part due to Ronny’s farming principles that La Soledad maintains a strict and aggressive pruning regimen of removing 20-30% of the farm’s branches at the end of each year, to combat disease, make coffee picking easier for the women and ensure efficient production year after year. The pruning program is part of a broader integrated farm management program that has seen a dramatic decrease of reliance on chemical inputs on the farm. The goal is to decrease chemical inputs by 80% in the longer-term through the implementation of this program. It was introduced to Ronny by a sweet pepper producer who has successfully decreased his chemical inputs to 10% and is one of the best sweet pepper producers in Latin America (based on a balance of quality & volume measures).

Though the couple is happy and motivated to continue coffee farming, they cite profitability as the farm’s biggest challenge. Land prices in the area are quite high and climbing, so balancing their wish to continue the coffee legacy of their family with the realities of coffee market instability keeps them revisiting the question of coffee’s viability every once in a while.

About Bella Vista & Zelcafé

Background

Luis Pedro Zelaya Zamora (LPZZ) is the fourth generation in his family to be working in the coffee business. The Zelaya family’s first farm was Carmona, followed by Bella Vista, which where the wet, dry mill facilities, and Zelcafé staff offices were later built and are currently located.

For many years, the family’s business focus was on commercial coffee production and export but in 2000, LPZZ began developing and changing Zelcafé’s focus into specialty coffee/microlots, with the support of some early clients. Over time Zelcafé has been able to successfully transition the business into solely focusing on specialty coffee. For the Zelaya family, their coffee endeavours are not only about business; their aim is to provide a good basis for generations of their family and community to come. With this in mind, they are constantly looking for ways to provide jobs to as many families in their communities as possible, as well as supplying the best quality coffee they can to their clients.

Partnerships & Services

The family has worked with small producers in Antigua since they first started coffee farming. New relationships almost always come from introductions from families already working with the Zelaya family, ensuring close and stable partnerships. In addition to buying cherries from farms, Bella Vista also manages estate farms that owners don't want to sell but don't know how manage themselves.

The Bella Vista team take care of all the planning, execution and monitoring of the resources each farm they own or manage have: human, technical, financial, and knowledge/training. In the case of the small producers that they buy cherries from, the team not only buy cherries at a premium, they also provide technical assistance and the financing of inputs. Bella Vista is constantly looking to improve its agricultural activities to reduce chemicals to a minimum and in turn share their scientific knowledge with other farms.

Sustainability & the Future

Bella Vista continuously encourages its workers to get proper education and in special cases, finances education for some of them. The facility also often offers workshops on different topics. The Zelaya family farms all have C.A.F.E Practices implemented and in the coming years the family will try to implement a WaSH project at one of their biggest farms.

Other future plans include research on water treatment and the building of treatment plants and hopefully, the construction of another greenhouse.

Ethiopia: Coming Back to Cooperative Coffee

Our Previous Relationships with Cooperatives via TechnoServe

During the initial phase of Technoserve’s (TNS) work with cooperatives in Ethiopia, Kaffa in Oslo imported green coffee directly (pre-CCS) and roasted a few lots from some of the TNS supported washing stations, including Yukro, Hawa Yember and Hunda Oli.

I first got involved with some of the TNS coops during the 2009/10 season. Groups of roasters from around the word were invited, particularly from USA and Scandinavia, as they were seen as discerning buyers in viable markets. TNS was presenting their work at SCAA, SCAE and at roasting community events. These presentations weren’t really within TNS’ self-proclaimed mandate nor model, rather it was done to train and empower local representatives to learn how to market themselves.

KAFFA bought some lots but service was slow, samples hard to get, lots were sold out before one had time to provide feedback, and even if one visited to cup and buy on-site, the unions seemed to favor the ‘bigger’ roasters. When ‘dealing’ with the coops, one quickly learned that they didn’t truly have control over their products. It felt like one had to scramble to get ahold of something rather than being able to pick and choose properly, the way we’d do it in, let’s say, Kenya. Commitments were certainly not honored. It was all quite discouraging.

When I re-visited at the end of the harvest in 2012, the cooperatives were not just under-funded; they’d had little to no money just before the beginning of the harvest to pay for cherries. When I additionally learned that the harvest had been very low, I initially thought the low volume had to do with little yield per tree/farm. In reality, the low volume was due to farmers not being able to afford to deliver cherries to places that couldn't pay them up-front. This in turn meant low volumes at the washing station. Coop washing stations could only purchase as much coffee cherries as their credit line allowed them to. The irony of the TNS coops’ credit drought was that Oromia Union, their partner-in-crime, didn’t lend their coops the resources needed to buy cherries and hence, thrive. Even though customers were lined up to buy, complete dysfunction ruled at the most basic levels.

The quality management of the cherries was also poor and this related to the above economic problems. When you’re struggling to pay in the first place, you end up scrambling to get what few cherries you can afford. This is not the time to be scrutinizing the cherries’ maturity and uniformity.

Just as discouraging was the administrative and fiscal dysfunction. I wanted us to stay away as long as the Oromia Union stayed involved.

Now, five years later, the time feels right on many levels. And I’d like to take this opportunity to reflect on our previous experiences, as well as provide some background info that will hopefully be helpful to you. Full disclosure: I am “collecting” this information from memory, so bear with the fact that some of it is anecdotal.

Former TechnoServe staff, Aansha Yassin

TechnoServe’s Coffee Initiative

TechnoServe (TNS) is an NGO that was founded in 1968 and has been funded by the likes of the Bill & Melinda Gates Foundation. TNS works with development initiativesin many countries including within Africa and mostly with agro-businesses — coffee amongst others — utilizing local natural resources and human potential to create economic advantages. What I like about the Gates Foundation approach is the clearly expressed belief that making good business (product and management) is both the means and the goal. In other words, participating communities utilize what they already have – local resources and the development of community members’ own knowledge and skills – to create better economic opportunities.

In Ethiopia, the Coffee Initiative was started in 2008 with investment from the Gates Foundation. This allowed TNS to do coffee work on a large scale and in new places like Ethiopia and this particular project had a five-year mandate. One of the beautiful ideas and high ambitions of the program was to empower local people to learn about the specialty coffee field by crafting great coffee: managing it as a business; doing lot separation; assessing quality through cupping; communicating monetary value through quality; and finally, marketing and offering it to a discerning marketplace.

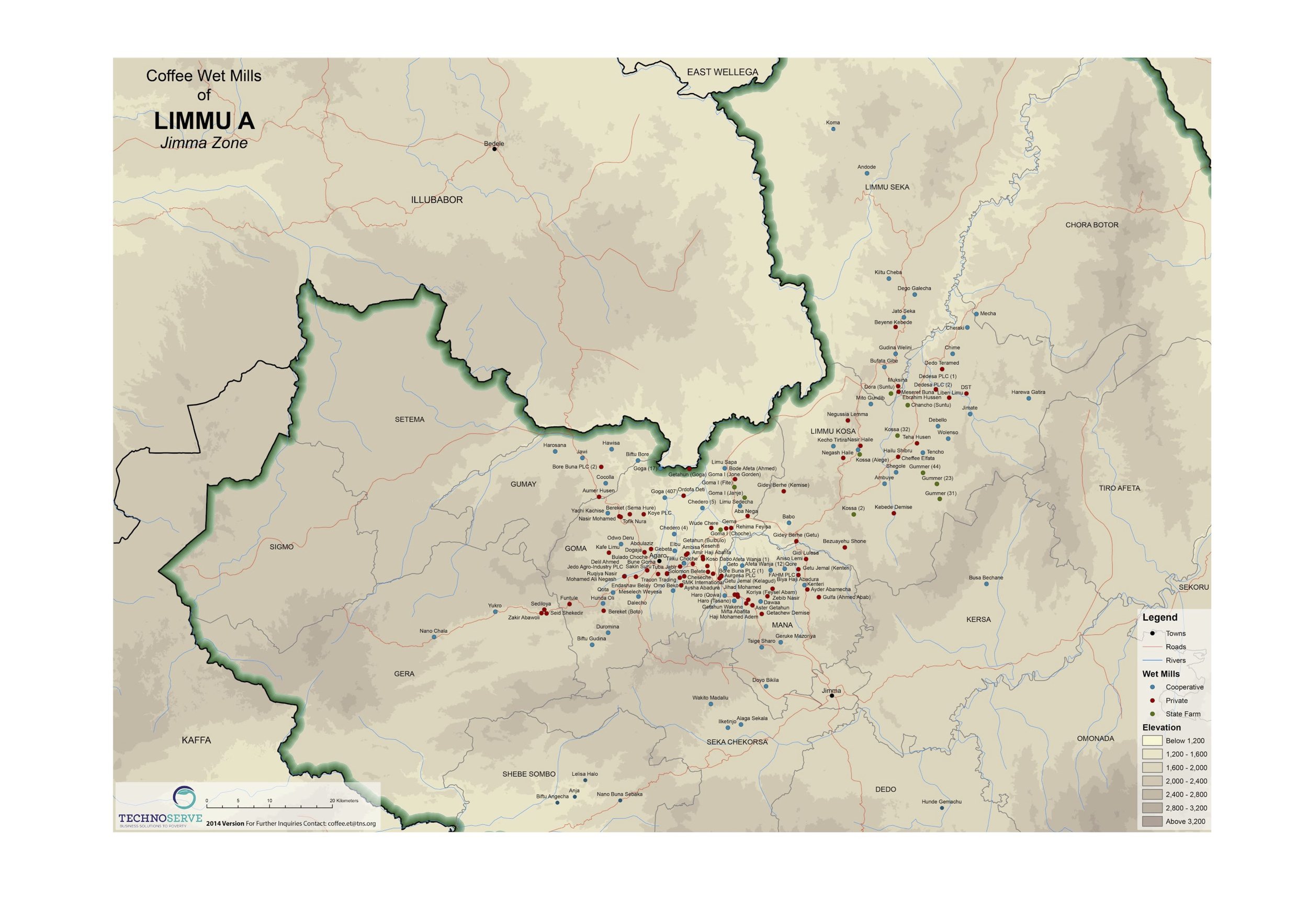

TNS intelligently set out to focus their efforts in the western regions of Ethiopia. This part of the country has always had a rich history in producing coffee. As far as we know, this was the birthplace of coffee. Still at the time that TNS came in, coffee from the west didn’t have fame, nor was it fetching the high prices coffees in the south were getting (such as e.g. washed Sidamo and Yirgacheffe).

The western lowlands are home to Bebeka Estate, which up until recently was the largest government owned estate farm. This estate is now owned by Mr. Al Amodi, who is also the current owner of the Horizon Dry Mill. Also located in this region, are areas such as Djimmah, which was synonymous with low grades of naturals.

Although many areas in the west do have the altitude for producing high quality coffee, the infrastructure wasn’t in place to produce and supply good coffee, whether because of the lack of equipment to produce it (very few wet mills), or getting products to the marketplace (poor roads). Thus, TNS’ strategy was to change the perception of West Ethiopian coffee by both efficiently producing washed coffeefor a specialty coffee market, and by making this coffee logistically accessibleto the market. Though roads were built and upgraded independently of TNS initiatives, these kinds of efforts went hand-in-hand.

The TechnoServe Way

TNS proposed that the coops install eco-pulpers at all the washing station projects they got involved with. This was a controversial prospect at the time, given the strong tradition up until then of the Ethiopian wet process being about fermenting with mucilage before washing. As we know, eco-pulpers have benefits, including saving water and requiring a lower up-front investment than the traditional wet process set-up with its many large fermentation tanks and washing channels.

Part of the TNS agenda was to help build equitable business projects, even helping with the financing, implementation of transparent bookkeeping, and overall good management by:

- Facilitating the process of applying for and getting loans to buildthe technical infrastructure: buying eco-pulpers, building washing stations and drying beds;

- Facilitating the process of applying for credit from banks so the coop could buy cherries. When a farmer arrives with coffee cherries, on any given day, the coop is expected to pay for the delivery on the spot. Thus, a lot of cash is required even before the start-up of the harvest season. Not to mention all the cash required to carry out the season;

- Helping to create a marketing plan (on behalf of the union): market outreach, market access, quality control and sample distribution

- Operational management, planning, and fiscal control.

Some of the most successful TNS coops managed to pay back the investment of equipment and infrastructure in less than 2 years, which is considered a great success by any business standard.

The ECX

TechnoServe During the time of the Revamping ECX

Little did TNS know that their program would be in stark contrast to ECX’s coming implementation of anonymity in the auction process. The new ECX structure was coincidentally put in place very soon after the TNS cooperatives were inaugurated and ready to hit the market with their attractively traceable coffees. The Coffee Initiative's original intention in Ethiopia was never to work with the Unions. In the first year, 2009, it tried to create a model where coops could work directly with private exporters. However, the Unions/government brought this process to a grinding stop. Eventually, all the coffees had to be taken over and exported by the Unions, and the contracts renegotiated. This was a major blow to the program because no one, including TNS, trusted that the Unions would be efficient, transparent, etc.

Specialty coffee buyers were flocking to TNS’ washing station projects. Although the coffee quality was not top-notch in the very beginning, the model at least provided a transparent trade model and TNS was pushing to make sure the farmers and their communities were rewarded with premium prices above the Fair Trade/Organic models.

When a washing station is owned by a cooperative, the contributing farmers collectively own the coop, but they must nominate a union to handle their milling and marketing for which the coop is charged a service fee. It usually makes sense to get these services from a union that is involved in the region, and hopefully it is also offering competitive terms. Even if the milling fee is regulated by law, unions have a reputation for taking advantage of the coops by charging the maximum fee possible and/or screening and processing lots to their own benefit (e.g. ‘mixing up’ lots, blending and even stealing).

The coop-union relationship is generally one where the union arguably has the ‘upper hand’. Since the union ends up with the parchment coffee in their possession, and being that they become the party that markets the coffee, they are the ones to send samples out to potential buyers.

In other words, even if a union is intended to be an intermediary part in the transparent relationship between a producer and a buyer, the unionis the primary contact and by default becomes the ‘owner’ of the relationship.

All this said, that dynamic briefly changed as soon as the TNS coops and washing stations earned their own fame, consequently bypassing the unions in building relationships directly with their end buyers (roasters).

TNS coops were obliged to deliver to various unions, as made geographic sense. Unfortunately, this only lasted for the first year of operation under TNS supervision. Once the Oromia Unionand its powerful and charismatic leader saw the success and prestige associated with trading directly with affluent coffee buyers around the world, it didn’t take long before all the TNS coops were forced to mill and market their coffee through the Oromia Union.

Oromia Union’s experiencewith lot separation, handling of the respective samples, and the necessary marketing efforts were generally not well developed initially. To overcome this, TNS opened regional offices with cupping facilities, training local staff and offering opportunities for buyers to access coffee without having to depend on the union. These efforts were meant only to be an temporary solution, while Oromia Union was supposed to equip itself with skilled staff, adequate systems and protocols, and building marketing strategies.

In my opinion this became and remained the weakest link with the TNS-developed supply chain. When TNS ended their project term, Oromia was still struggling to get things right.

Limmu is primarily where our coop coffees this year will come from

Returning to Cooperative Coffee

I am very pleased to announce that CCS is going into this season with a more diverse approach to sourcing and buying in Ethiopia. In addition to offering stellar ECX coffees; and micro-lots from private estates; CCS will introduce cooperative coffees to the menu. It is promising indeed thus we are looking forward to presenting a carefully curated list of lots from thoughtfully selected coops in the Limu/Djimmah region of the west!

The reasons for this optimism are these necessary turn of events: 1) Other Unions, for all the above-mentioned reasons, have emerged to service the coops; and 2) Quality, compliance, and commitment seem to hold a higher priority than in the earlier years of my experiences with the cooperatives and the Oromia Union.

We cannot wait offer you to taste the 'fruits' coming from all these emergent changes. Enjoy!

Robert

—founder of KAFFA and Collaborative Coffee Source (CCS)

Corrections: 1) the previous version incorrectly stated that TechnoServe was founded by the Bill & Melinda Gates Foundation and has been corrected to reflect the fact that the NGO was founded in 1968 and that the Gates Foundation is one (albeit a large one) source of funding for TNS.

2) it was never TNS' original intent to work with Unions, as was implied in the earlier version. The post has been corrected to reflect the fact that TNS' aim was to work directly with cooperatives, independently of the Unions/government from the beginning.

Cupping back in 2012

Farmer Profile: Cresencio Izaguirre

Family Details

Farmer’s & Spouse’s names: Cresencio Izaguirre & Maria de Los Angeles Martinez Farmer’s Date of Birth: 10 June 1972

Children’s names & years of birth: Ruber Joel (1999); Ingrid Jackeline (2000); Jairo Nahun (2002); Lusby Roxeni (2005); Yeldy Maritza (2008); Seiri (2010)

Year farmer received/purchased first coffee farm: 1989

About Cresencio & his family

Cresencio comes from a coffee growing family; he is a second-generation farmer. His brothers (Bernardo, Glenis & Juan Angel) and mother (Maria Adilia) own their own coffee plantations, which neighbour Cresencio’s plantations. Together, the family share drying facilities and are currently constructing a beneficio/wet mill. His current focus now that he has purchased more land, is to build a new house for his family.

When asked why he chose coffee farming, Cresencio responded that coffee provides a stable income. He also wanted to continue the coffee farming legacy of his parents. When asked what his biggest accomplishment has been to date, Cresencio responded that he is most proud of the fact that he is a coffee producer. According to Cresencio, the biggest challenge he faces in relation to coffee production is disease, like “roya”, along with not having enough resources to fight them.

Farm & Production Data

Closest town: El Cedral

Region: Santa Barbara

Altitude: Three plantations: 1. 1600 masl; 2. 1580 masl; 3. 1580 masl

Farm Size: 3.8 ha

Approximate number of trees planted per hectare: 2450

Soil composition: Volcanic

Harvest season: January to June

Harvest peak: March

Approx. annual production: 15 bags (per 69kg)

Variety: almost 100% pacas with a few bourbon plants

Process: dry fermentation for 24 hours, then washed 3-4 times with agitation

Other Data

Other crops grown: corn & beans for family’s own consumption

Percentage of income coming from coffee production: 100%

Number of people employed at farm: 5 pickers/seasonal workers + family

Pickers’ wage: 50 HNL/5-gallon bucket

About the Farm & Coffee

Cresencio’s coffee production comes from three separate plantations (as noted above) and in 2015, Cresencio purchased more land at a lower elevation. This plot was already planted with coffee (of the bourbon variety), which Cresencio stumped, meaning the re-growth will begin producing in 2018. Most Cresencio’s production is from the pacas variety, with maybe one bag of bourbon. We’ll see the bourbon production increase once the newly purchased and stumped plantation is producing again. For the first time (2017), Cresencio has agreed to separate out his bourbon production, even though this will only produce about a bag. Both he and we are curious about what the cup profile will be.

Cup profile: Guava, nectarine, hints of pine in the aroma. Starfruit, dried nectarine, some citrus peel, pear-like in the cup.

The Relationships

We were introduced to Cresencio by our good friends and exporters, San Vicente, based in Peña Blanca, the closest city to almost all the farmers we work with in Honduras. San Vicente has been an invaluable partner to us, helping the development process of our relationships with the farmers with whom we work, introducing us to new potential partners, providing milling & logistic services, and actively working together with farmers on new strategies to improve farm-level practices to improve cup quality each year.

Background to Santa Barbara

The villages Cielito, Cedral and Las Flores follow one after another along the mountain range in Santa Barbara. Grown on this hillside is mostly Pacas, a coffee species akin to Bourbon, as well as Yellow Catuaí and Pacamara. It is challenging to process coffee cherries in areas like these, which are close to the jungle and thus, to rain. The drying process is especially demanding. But when these processes are precisely controlled, seemingly problematic factors (like drying under challenging conditions) are what make coffee from this area particularly interesting. The coffee produced here cups with flavour attributes not found anywhere else in Central America.

Since 2005, the region, Santa Barbara, and the small producers living and working there, have shared the distinction as the place and the people producing exceptional coffee within Honduras. Our work and the

beginning of the on-going relationships we’ve since established here began during the 2005 Cup of Excellence. We came to realize that there are exceptional producers from this small area. And since that inaugural year, we have purchased from over twenty different Santa Barbara producers.Located in the village of Pena Blanca is coffee exporter San Vicente – the company that coordinates the coffee we buy from Santa Barbara. Over the past several years, one particular hillside has become the largest supplier of CoE winners in Honduras. The most successful farms with the smartest and most innovative farmers are neighbours on this hillside and they help each other to refine the best of their lots.

There exists an eagerness here; a willingness, motivation and ambition to produce the best coffee in the country. But there are also large differences amongst the farmers and our purpose is to be close to this special coffee community and get to know the most ambitious of the farmers here; the ones we can develop something with. In order to build relationships – that allow both parties to have a common understanding of quality coffee – there must be frequent and long-term presence.

To produce coffee that tastes fruity is not very complicated. But to produce coffee that is clean, clear, fresh and fruity – that’s an art. One of the biggest assumptions within specialty coffee is that coffee from high- altitude areas naturally exhibits these characteristics. But high elevation can lead to potential problems, even in tropical climates.

In the highest areas of Santa Barbara, up to and over 1800 meters, producers can experience “freezing”: the combination of temperatures between 4-5C and rainfall that combine to cause cherries to not ripen and leaves to die on the bush. These conditions create a cold and humid climate, which is hazardous for processing and requires steady and reliable drying conditions for coffee so quality will not deteriorate. These natural conditions, of course, cannot be evaded. But clever and prescient coffee farmers, like the ones we collaborate with, invest in drying systems that minimize the risks associated with weather.

Farm Profile: Buena Vista

Farm & Production Data

Farm Name: Buena Vista

Owner: Luis Pedro Zelaya Aguirre

Farm manager(s): Carlos Patal (daily operations); Franklin Quiche (overall)

Closest town: Jocotenango

Department: Sacatepéquez

Altitude: 1772-1900 masl

Farm Size: 80 ha

Approximate number of trees planted per hectare: 3200

Soil composition: Clay mixed with volcanic and sandy loam

Harvest season: December to April

Harvest peak: February to March

Approx. annual production: 1330 bags (per 46kg bags)

Variety: 25 ha planted with bourbon; 6 ha planted with caturra; 3.5 ha planted with catuaí; 3.5 ha planted with villa sarchí; 15 ha planted with catimor.

Wet process

Washing

- Cherries go into reception tank and floaters are separated out, then pumped into the depulper

- After being depulped by a mechanical depulper, cherries are sorted in two ways: clean and those that still have fruit

- The ones with fruit go to a separate channel to undergo a second depulping

- Clean cherries are moved with recycled water over to fermentation tanks

- If there happen to still be cherries with fruit, they are sent to another tank where they will most likely be processed as commercial grade

- Dry fermentation for 14-15 hours

- Clean water then used to rinse the parchment which is then moved to a mechanical washer and finally transported to the drying patios or beds.

Three types of drying methods. Dependent on quality:

Green house with raised beds

- Used for small lots (e.g. Hunapu). Do some honeys and naturals

- Temperature, moisture, humidity levels are monitored

- There are windows that can be opened to allow for more air flow when needed

Mechanical dryers used for biggest/commercial lots

- Stay in the dryer for 24 hours @ below 50C

- Then dried for five days on the patio

Patio

- Most volume dried here

- 12-16 days

- Tube test in the middle of coffee lots to figure out whether coffee is dry enough to be measured for 11% moisture content. If it sticks to the tube, it still needs drying. If it doesn’t, moisture content reading is taken.

Post-drying

- Parchment is packed in grain pro and rests for 30 days

- At the dry mill, there are three different mechanical sorters that grade by A (biggest), B and C (smallest)

- This process is repeated at least seven times to ensure even grading

- Finally, the coffee is deparched and packaged.

Other Data

Number of people employed at farm: 18 permanent; 100-150 temporary/seasonal pickers. A law was recently passed in Guatemala that requires employers to register workers as employees and this provides them with government social and healthcare benefits that they didn’t previously have access to.

Pickers’ wage: 50-70 GTQ/45kg.

About the farmer & plans for the farm

Luis Pedro Zelaya Aguirre is the patriarch of the Zelcafé group of companies, which includes Bella Vista Mill (see below) and several farms either owned or managed by the group. Buena Vista has been under LPZA’s management since 1998 and the farm has been planted with coffee since 1991.

The biggest challenges for Buena Vista are disease (especially roya) and drought.

Projects include replanting all the catimor with gesha (seeds coming from Finca Carmona, a farm owned by a relative of LPZA’s, Maria Zelaya) and replanting a plot of 3 ha currently planted with bourbon & caturra with a newer bourbon strain that grows shorter (easier to pick) and has a better cup profile. 1 ha of Buena Vista has been planted with the java variety and will first harvest next season.

The farm’s coffee trees are fully replanted every 30 years, with the first pruning cycle occurring after seven years. Pruning occurs every year, while stumping occurs every third year.

About Bella Vista & Zelcafé

Background

Luis Pedro Zelaya Zamora (LPZZ) is the fourth generation in his family to be working in the coffee business. The Zelaya family’s first farm was Carmona, followed by Bella Vista, which where the wet, dry mill facilities, and Zelcafé staff offices were later built and are currently located.

For many years, the family’s business focus was on commercial coffee production and export but in 2000, LPZZ began developing and changing Zelcafé’s focus into specialty coffee/microlots, with the support of some early clients. Over time Zelcafé has been able to successfully transition the business into solely focusing on specialty coffee. For the Zelaya family, their coffee endeavours are not only about business; their aim is to provide a good basis for generations of their family and community to come. With this in mind, they are constantly looking for ways to provide jobs to as many families in their communities as possible, as well as supplying the best quality coffee they can to their clients.

Partnerships & Services

The family has worked with small producers in Antigua since they first started coffee farming. New relationships almost always come from introductions from families already working with the Zelaya family, ensuring close and stable partnerships. In addition to buying cherries from farms, Bella Vista also manages estate farms that owners don't want to sell but don't know how manage themselves.

The Bella Vista team take care of all the planning, execution and monitoring of the resources each farm they own or manage have: human, technical, financial, and knowledge/training. In the case of the small producers that they buy cherries from, the team not only buy cherries at a premium, they also provide technical assistance and the financing of inputs. Bella Vista is constantly looking to improve its agricultural activities to reduce chemicals to a minimum and in turn share their scientific knowledge with other farms.

Sustainability & the Future

Bella Vista continuously encourages its workers to get proper education and in special cases, finances education for some of them. The facility also often offers workshops on different topics. The Zelaya family farms all have C.A.F.E Practices implemented and in the coming years the family will try to implement a WaSH project at one of their biggest farms.

Other future plans include research on water treatment and the building of treatment plants and hopefully, the construction of another greenhouse.

Acevedo Cup: Recap

The CCS Acevedo Cup 2018 Awards Ceremony

The inaugural Acevedo Cup was one of the most inspired/inspiring events CCS was a part of in 2016. What a motivating way to finish off the year. It’s difficult to imagine just how much preparatory work the Fairfield team had done in advance of the competition but the resulting four days we spent cupping, discussing, scoring and ranking the top 20 lots were an absolute pleasure.

Those of you who’ve cupped at origin know how arduous full cupping days can be, so the fact our group of judges enjoyed cupping and re-cupping these coffees says everything about the standards to which the Fairfield team operates.

This competition was a great way to start our work in the Acevedo municipality of Huila. It gave us the opportunity to taste a wide variety of cup profiles available within this community, while the closing ceremonies, in turn, gave the community the opportunity to learn about CCS’ and Fairfield’s work and ambitions for working in and around Acevedo.

Between 20-30 families came to the closing ceremonies and while many of them weren’t “winners” in the sense of having submitted top-20 coffees, it was fascinating to speak with several of the families afterward and learn about their perceptions not only about the competition, but about how they view working with Fairfield and us in the long-term. Some well-established community leaders were in attendance and they had already decided to organize meetings amongst Acevedo Cup winners and their neighbours to first discuss the winners’ protocol and strategies for the winning lots, and then determine how and what strategies neighbouring farms could implement to improve their own production.

Left to right Eduardo Urquina of Fairfield Trading, Miller Bustos collecting the certificate for his brother Fernando Bustos, and Alejandro Renjifo of Fairfield Trading.

Field Notes

Day 1

Calibration round + two competition tables. Screened 29 coffees down to 12 which will move on to the next round.

Learned about the National Learning Service (SENA), a government initiative that provides workers, adults and youths with technical training within the areas of industry, trade, agriculture, mining and cattle breeding. Some of volunteers helping with the Acevedo Cup are students of SENA and are currently undergoing training to become professional baristas, cuppers and roasters.

Day 2

Screened 29 coffees down to 12. Day 3 is the cupping of the top-24 coffees from Days 1 & 2.

First introduced to the winning coffee which I described as one of the best coffees I cupped all year. I gave it a score of 93 points with the following aroma/flavour descriptions: a floral, lemony, jasmine, and bergamot aroma. Cup is complex, juicy, well-structured, citrusy, clean, with a red currant finish. This coffee has all the elegance of great washed Ethiopian coffees, while also maintaining a Kenyan-like acidity.

Day 3

Top-24 coffees screened down to top-20. Ranks 11-20 determined today; top-10 will be cupped and ranked on Day 4.

Visited Los Angeles farm, owned by Maria Bercelia and her partner, Jose Erazo. We purchased coffee from them for our first ever shipment from Acevedo and are pretty certain at least one of their coffees will be amongst the winning coffees.

Day 4

Final round/table of top-10 coffees.

Winners, lot sizes (per 70kg bags) and varieties are as follows:

#10: Jhon Wilson Poveda, 11 bags, Colombia & Caturra

#9: María Bercelia, 15 bags, Colombia & Caturra

#8: Otoniel Morales, 7 bags, Castillo

#7: Nicolas Delgado, 18 bags, Colombia & Castillo

#6: Ciro Lugo, 12 bags, Colombia

#5: Elizabeth Abaunza, 5 bags, Caturra

#4: Ciro Lugo, 12 bags, Colombia

#3: Alexander Ordoñez, 12 bags, Colombia & Tabi

#2: Fernando Bustos, 18 bags, Colombia

#1: Jesucita Cuellar, 5 bags, Tabi

Jesucita is a new grower to Fairfield and the Fairfield cupping team hypothesized that this coffee would win the competition during their screening of all the coffees submitted for competition. Must learn more about the Tabi variety!

Ciro Lugo won 4th and 6th place.

Final Notes

A big thank you to our three roaster judges:

Ria Neri, Four Letter Word, Chicago, IL

Tali Robbins, Barismo, Cambridge, MA

Dillon Edwards, Parlor Coffee, Brooklyn, NY

The remainder of the judging panel were Ana Beatriz Bahamon, Eduardo Urquina Sanchez, Esnaider Ortega & Alejandro Renjifo, all of Fairfield Trading; along with David Stallings & myself, who represented CCS.

Until next time,

Melanie

Kenya: The Backward Rise of the Small Estate Farm

Connecting quality coffee with specific farms and their owners has become the specialty coffee norm, which emphasizes cup score, long-term relationships, and transparency. This bodes well for smallholders and roasters alike, as these expectations point to an evolving market; one that is slowly shifting away from purely speculative pricing and is now favouring connections between specific people selling and buying to/from one another.

Kenya, then, has been anomalous from other specialty origins in that much of its best quality lots are sold through a centralized auction and come from cooperatives serving up to 2000 smallholder members each. But contrary to other origins, many of Kenya’s coffee farmers’ cooperatives are impressively run organizations. Many of them actually accomplish what so many cooperatives in other origins fail to do: provide services and disseminate information that help farmers grow great coffee which in turn attracts buyers willing to pay good prices. Kenyan coffee cooperatives are in fact so successful, that some of the highest quality lots in the world come from them: AA and AB lots produced by cooperative factories are consistently the most expensive commercially traded coffees in the world.

To understand how and why coops became so strong, let’s go back to the beginnings of how Kenyan coffee was traded.

A Brief History of the Kenyan Coffee Auction

In the beginning (pre-Depression era), coffee was sold by London traders who took up to six months after the coffee was shipped before paying the farmers. Farmers had to rely on banks to finance them during this period, as well as pay for shipment costs. Further depleting their returns was the fact that coffee was initially dry milled in London, rather than in-country.

By 1926, the Coffee Planters’ Union was established with the aim of helping producers both make better coffee and more money from it. The 1930s was a time of rapid changes within the Kenyan coffee industry with various groups trying different kinds of cooperative and marketing systems, with the result that the Planters’ Union began splitting into smaller cooperative societies. The Thika Planter’s Cooperative Union became the largest and most dominant of these factions, which eventually was replaced by the Coffee Board of Kenya (KPCU), due to political lobbying from farmers and traders.

Until this point, the various planters’ unions and then the Coffee Board of Kenya had focused their efforts on gaining control over processing and curing coffee. So far left out of these movements was the gaining of genuine control over the marketing of Kenyan coffee. The auction was thus borne from the impetus of Kenyan farmers who wanted to gain control over the marketing of their coffee.

The first auction was established in 1931 but did not overthrow the prominence of the London traders. Several other auctions followed to varying degrees of success until in 1937, when the Nairobi Coffee Exchange was opened to widespread support. In addition, a nationwide standard in grading was developed in 1938. This became controlled by the KPCU.

The Rise of the Coffee Smallholder

Land ownership rights will always determine how a coffee sector is structured. With Kenya’s colonial history, early coffee production was represented and controlled by colonial land owners. In 1946, the government (still colonial) began to open rules for who could grow crops where and actively began encouraging indigenous Kenyans to grow cash crops, including coffee.

Then in 1954, a local chief got coffee seedlings from a European friend and began to plant on his farm. While he was initially subject to criminal proceedings, the growing independence movement (“Mau-Mau rebellion”) aided the chief in having his case successfully dropped. Once the rebellion ended, the Director of Agriculture removed restrictions previously allowing for only large plantations to grow coffee. The smallholder revolution had begun.

These days, Kenyan coffee is made up of two main sectors: plantations, made up of ±3,300 farms comprising an area of ±40,000 hectares (ha) of coffee. Within the plantation sector, there are 3000 small estates (<50 ha) and 300 large estates (>50 ha). This accounts for about 25% of Kenya’s coffee planted land. The other 75% is comprised of the coop sector, made up of 270 cooperatives with a membership totalling 700,000 smallholder farmers cultivating 120,000 ha of coffee.

Smallholder cooperatives began building factories/washing stations in the 1960s so that they could process their coffees the way large plantations did. Nowadays, these factories serve up to 2,000 members each. Smallholders, overall, control of 58% Kenya’s coffee production. Not only do they contribute the largest proportion of coffee, they are known for producing the highest quality coffee coming out of Kenya.

Changing Times: The Rising Small Estate Farm

Given Kenya’s coffee history, it is unsurprising that the cooperative has been the dominant seller of Kenyan specialty coffee. Specialty coffee buyers are very used to working with cooperatives and marketing Kenyan coffees in this way. But not all cooperatives are working equally well and it has often proved frustrating for a buyer to align themselves with specific coops and/or factories because of things like corruption, mismanagement issues, and fluctuating quality.

It is for these reasons, traceability concerns, etc., that we have started exploring relationships with both single estates as well as small farmer groups beginning to form micro-coops. As is true at origins with well-developed farm-level marketing, these kinds of partnerships are enticing for even greater quality and relational potential than is possible with big group organizations.

While touring Kirinyaga during early-November this year, we met with the newly established “Slopes of 8” micro-cooperative. As its name implies, this cooperative is made up of eight estates that have banded together to market their coffees together with the aim of establishing long-term relationships with buyers. The project has garnered so much interest from neigbouring farms that the leader of Slopes of 8, Joseph Karaba, is consulting others on how to begin their own micro-cooperatives.

In February, we will hopefully cup lots from a couple of these newly established coops and start some new partnerships.

We have already had a lot of success with one small estate farmer relationship that was established two seasons ago: John Njoroge owner of Kiambu and Kiriani estates, who has produced great coffees for us two seasons in a row. The current harvest will represent our third season working with him and we were thrilled to see that he had invested in and constructed beautiful, sturdy, shaded drying beds, even though the drought brought on by El Niño/La Niña earlier this year has left him with a disappointing volume of coffee this season.

Unfortunately for farmers all over Kenya, the current harvest will lead to lower than average volumes this year, which often leads to higher overall cup quality. Look forward to sharing our selections with you in a few months.

-Melanie

Bibliography

- Block, R. Pearson & C. Tomlinson. Kahawa: Kenya’s Black Gold. C. Dorman LTD. Nairobi, 2005.

Situation in Ethiopia

Over the last nine months, there have been waves of protest and unrest occurring in the Oromia region, which has led us to cancel our planned trip to Ethiopia in the coming weeks. Amidst the protests and subsequent killings, we have read about and had confirmed by export partners, that washing stations have been targets of looting and vandalism. For one of our partners in particular, it has been incredibly challenging to make decisions about buying and processing cherries. Would these coffees even make it out of the country?

While it's challenging to find good news sources about how and why these protests have been occurring, we've found some that we'd like to share with you and that you can find in the links below.

(Very) Surface Background

The current situation is based on the build up of years of frustration from ethnic groups who have felt marginalized by the government. Ethiopia is made up of about 80 different ethnolinguistic groups with the Oromo nation comprising the largest ethnic group in the country. The communist regime was overthrown in 1991 and the current government, which acts essentially as a single-party, has been ruling as an authoritarian regime since that time.

Throughout the years, there have been varying degrees of unrest and protest, the biggest and until now occurring in 2005 during the country's heavily contested elections. The results of that election, which sustained the ruling party's power (the Ethiopian People's Revolutionary Democratic Front (EPRDF)), was considered fraudulent by both the opposition as well as outside observers. Now, the country's two largest regions - Oromia & Amhara - have been continuously erupting in protests over the last nine months, over similar dissatisfactions with the ruling EPRDF, despite the EPRDF's attempts to repress these uprisings through thousands of arrests and hundreds of killings.

The heart of the protestors' frustration comes down to a few main topics: land ownership, repression, and the fact that the ruling party is significantly made up of a minority Tigray elite. The Tigray nation makes up just 6% of Ethiopia's total population.

Potential Impact on the 2016/17 Harvest?

Those of you who have spent time in Ethiopia, or in the East African region more generally, understand that change is the modus operandi. It is too early in the season to make any predictions about how the export season will play out and whether these sociopolitical happenings will negatively impact the coffee sector.

For now, we wanted to share what is happening and why we and other coffee buyers have been cancelling travel plans to Ethiopia. We will keep you updated as further news becomes available.

News Links

http://hornaffairs.com/en/2016/09/14/ethiopian-spring-killing-grievances-protests/

http://addisstandard.com/7784-2/

http://www.bbc.com/news/world-africa-36940906

Helpful Reports for Background Info

http://graphics.eiu.com/PDF/Democracy_Index_2010_web.pdf

https://www.hrw.org/world-report/2006/country-chapters/ethiopia

Farm Profile: El Pilar

Region: San Juan Sacatepéquez

Average altitude: 1520-1920 msnm

Coffee area size: 90 hectares

Coffee Varieties: Bourbon, Caturra, Catuaí

Shade: mixed

Owner: Juan Carlos Chen

Managed by: Juan Carlos Chen

Harvest season: January- March (Peak: last days of February and the beginning of March)

Flower Season: May

Annual rainfall: 950 mm

About El Pilar

El Pilar is located just outside of Antigua and is owned and managed by Juan Carlos Chen. The farm area is over 1900 hectares of which 90 hectares are dedicated to coffee. The varieties grown here are Bourbon, Caturra and Catuaí. The agricultural management is starting to be stricter, especially when it comes to plant nutrition and Juan is looking to produce with a sustainable focus in mind. This focus is evident in the fact that the land not being used for coffee cultivation is managed as a natural reserve. Most of the farm’s activities are focused on conservation.

When it comes to coffee, a mix of organic activities take place in order to keep conventional agriculture techniques as a last resource. All the tissue taken from the plants turns into organic manure for the plants, chemicals to control diseases and pests are the last option and implementation of soil sampling with satellite technology is the newest innovation at the farm, in order to have a strict fertilization protocol. This technology helps the use of as little chemical fertilizer as possible, which in turn helps to avoid the contamination of groundwater.

About Bella Vista & Zelcafé

Background

Luis Pedro Zelaya Zamora (LPZZ) is the fourth generation in his family to be working in the coffee business. The Zelaya family’s first farm was Carmona, followed by Bella Vista, which where the wet, dry mill facilities, and Zelcafé staff offices were later built and are currently located.

For many years, the family’s business focus was on commercial coffee production and export but in 2000, LPZZ began developing and changing Zelcafé’s focus into specialty coffee/microlots, with the support of some early clients. Over time Zelcafé has been able to successfully transition the business into solely focusing on specialty coffee. For the Zelaya family, their coffee endeavours are not only about business; their aim is to provide a good basis for generations of their family and community to come. With this in mind, they are constantly looking for ways to provide jobs to as many families in their communities as possible, as well as supplying the best quality coffee they can to their clients.

Partnerships & Services

The family has worked with small producers in Antigua since they first started coffee farming. New relationships almost always come from introductions from families already working with the Zelaya family, ensuring close and stable partnerships. In addition to buying cherries from farms, Bella Vista also manages estate farms that owners don't want to sell but don't know how manage themselves.

The Bella Vista team take care of all the planning, execution and monitoring of the resources each farm they own or manage have: human, technical, financial, and knowledge/training. In the case of the small producers that they buy cherries from, the team not only buy cherries at a premium, they also provide technical assistance and the financing of inputs. Bella Vista is constantly looking to improve its agricultural activities to reduce chemicals to a minimum and in turn share their scientific knowledge with other farms.

Sustainability & the Future

Bella Vista continuously encourages its workers to get proper education and in special cases, finances education for some of them. The facility also often offers workshops on different topics. The Zelaya family farms all have C.A.F.E Practices implemented and in the coming years the family will try to implement a WaSH project at one of their biggest farms.

Other future plans include research on water treatment and the building of treatment plants and hopefully, the construction of another greenhouse.

Farm Profile: La Florida

Region: Patzun Chimaltenango

Average altitude: 1805 masl

Farm size: 21 hectares

Wet mill: Florida

Dry mill: Bella Vista

Coffee Varieties: Bourbon, Typica, Caturra, Catuaí, Pache

Shade: Native trees, Gravileas, Ingas

Owner: Rodolfo Benavente

Managed by: Víctor Hugo Juárez

Harvest season: February- April (Peak: beginning of March)

Annual rainfall: 1200 mm

About La Florida

La Florida is owned by Rodolfo Benavente, who has worked in the coffee world pretty much all his life. The farm is managed by a relative, Víctor Hugo Juárez, and Victor has been steadily improving the management of the farm every year by, for example, “stumping” the older trees (80 years old!) in order to renew the trees’ tissue and increase productivity. Stumping is a pruning practice wherein the tree’s stem is cut down to just 10-15 cm above the soil. As one can imagine, this practice is a huge investment, given the length of time it takes for the plant to regenerate and produce cherries again.

Although this practice has given the family a hard time, they understand the long-term benefits of it and results are starting to show: increased quality and productivity. As well, keeping the old trees which have historical significance to the family. Additionally, the family is starting to plant new varieties.

La Florida experiences a late harvest due to the altitude, so the harvest season goes from the beginning of February to the end of April. There are two to three rounds of hand-picking (with consistent people year to year) and the coffee is sorted at the wet mill located at the farm. Drying takes place on the farm’s own patios too.

Bella Vista is able to get La Florida’s coffees with the help of Byron Benavente (Rodolfo’s son), who helps outsource coffee from that area. Byron has also facilitated help/consulting for the family to improve in agricultural management and processing at the wet mill.

About Bella Vista & Zelcafé

Background

Luis Pedro Zelaya Zamora (LPZZ) is the fourth generation in his family to be working in the coffee business. The Zelaya family’s first farm was Carmona, followed by Bella Vista, which where the wet, dry mill facilities, and Zelcafé staff offices were later built and are currently located.

For many years, the family’s business focus was on commercial coffee production and export but in 2000, LPZZ began developing and changing Zelcafé’s focus into specialty coffee/microlots, with the support of some early clients. Over time Zelcafé has been able to successfully transition the business into solely focusing on specialty coffee. For the Zelaya family, their coffee endeavours are not only about business; their aim is to provide a good basis for generations of their family and community to come. With this in mind, they are constantly looking for ways to provide jobs to as many families in their communities as possible, as well as supplying the best quality coffee they can to their clients.

Partnerships & Services

The family has worked with small producers in Antigua since they first started coffee farming. New relationships almost always come from introductions from families already working with the Zelaya family, ensuring close and stable partnerships. In addition to buying cherries from farms, Bella Vista also manages estate farms that owners don't want to sell but don't know how manage themselves.

The Bella Vista team take care of all the planning, execution and monitoring of the resources each farm they own or manage have: human, technical, financial, and knowledge/training. In the case of the small producers that they buy cherries from, the team not only buy cherries at a premium, they also provide technical assistance and the financing of inputs. Bella Vista is constantly looking to improve its agricultural activities to reduce chemicals to a minimum and in turn share their scientific knowledge with other farms.

Sustainability & the Future

Bella Vista continuously encourages its workers to get proper education and in special cases, finances education for some of them. The facility also often offers workshops on different topics. The Zelaya family farms all have C.A.F.E Practices implemented and in the coming years the family will try to implement a WaSH project at one of their biggest farms.

Other future plans include research on water treatment and the building of treatment plants and hopefully, the construction of another greenhouse.

Farm Profile: Chuito

Region: Antigua

Altitude (masl): 1500-1900

Farm size (ha): 44

Wet/Dry mill: Bella Vista

Varieties: Bourbon, Caturra, Villa Sarchí

Shade: Gravilea

Owned and Managed by: Luis Pedro Zelaya Aguirre

Harvest season: December- April (Peak: last days of January and the beginning of February).

Flower Season: May

Annual Rainfall (mm): 1200

About Chuito

Chuito is owned and managed by Luis Pedro Zelaya Aguirre – the owner and operator of Bella Vista Mill in Antigua. Varieties grown on the farm include Villa Sarchí, Bourbon, and Caturra and gravilea trees are used for shade: strict management of the shade is employed, as it is very important for the growing process. Renovations undertaken over Mr. Zelaya’s management of the farm has allowed for the separation of lots by variety and harvest days. Specialized agricultural activities overseen by Mr. Zelaya ensure good production yields and high quality. In addition, cherries are hand-picked by workers living near the farm, creating a good source of local employment.

After cherries are picked, they are taken to Bella Vista for wet processing and dry milling. Coffee is separated by day of picking, variety, and altitude. Once separated, the coffee is either sun-dried on patios, or dried in the greenhouse, which provides a controlled drying environment leading to better cupping results.

About Bella Vista & Zelcafé

Background

Luis Pedro Zelaya Zamora (LPZZ) is the fourth generation in his family to be working in the coffee business. The Zelaya family’s first farm was Carmona, followed by Bella Vista, which where the wet, dry mill facilities, and Zelcafé staff offices were later built and are currently located.